Ms Thesis: Pedestrian Femur Fracture Prediction

A quick look here can save lives!

Among all road users, pedestrians are particularly vulnerable and face a heightened risk of impact with vehicles resulting in injuries to head and legs. With the advent of autonomous driving technologies, minimizing these injuries to vulnerable road users has become increasingly critical.

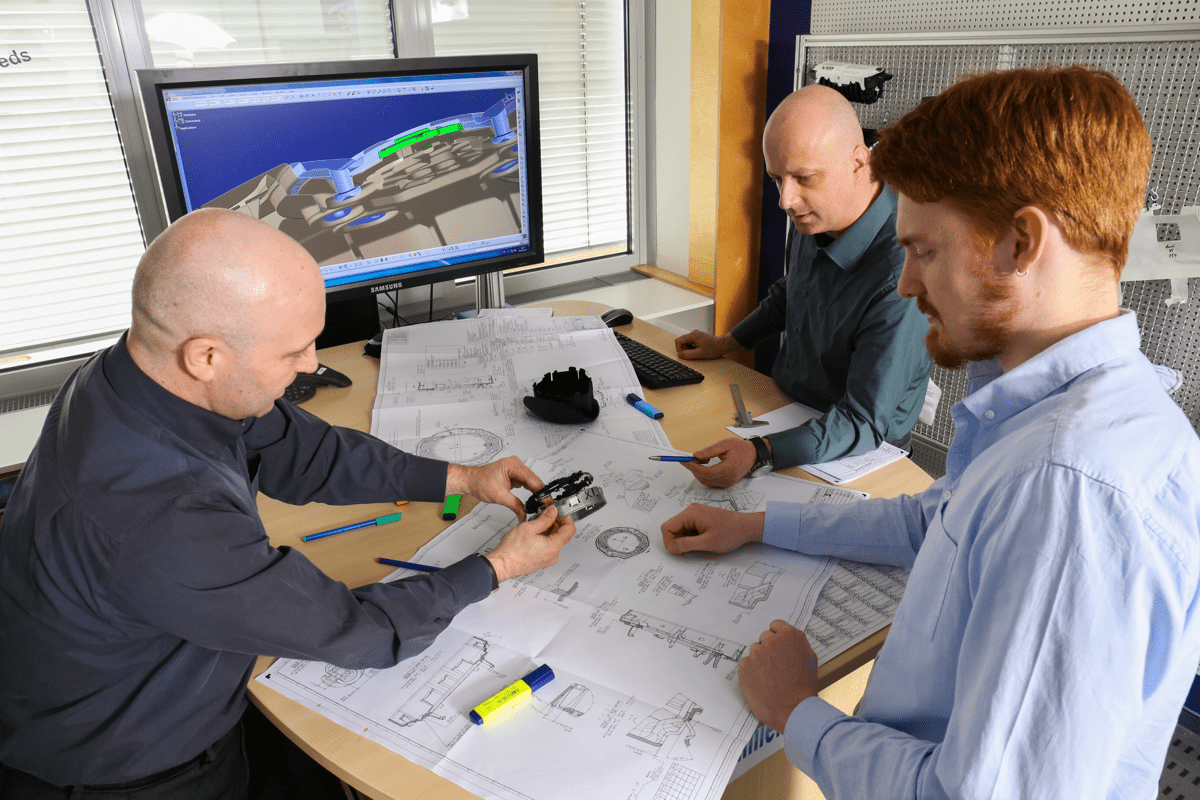

Currently, pedestrian safety in vehicle design is evaluated using physical impactors that approximate the biomechanical characteristics of a human leg. But these impactors have limitations in accurately predicting injury risk. Digital representations of the human body play a pivotal role in the development and optimization of advanced safety systems, enabling engineers to simulate these crash scenarios and design protective measures with greater precision.

The SAFER HBM is one such Finite Element (FE) Human Body Model (HBM) that is developed to predict risk of injury to occupants and pedestrians in crash scenarios. By being capable of predicting stress and strain in the modelled bones, it has the potential to predict the risk of fracture at the bone level.

In this thesis, a method will be developed that will enhance the capability of the SAFER HBM to predict upper leg fracture risk. The project will consist of FE HBM pre-processing in software such as ANSA or external scripts (Matlab/Python/R or similar). The updated model will then be simulated in both validation scenarios replicating biomechanical subsystem tests as well as in application studies in a vehicle-like environment.

Task description

- Review of relevant literature on, anatomy lower extremity injuries with a special focus on pedestrian injuries, experimental reference tests, and previous FE modelling of fracture risk

- Develop a risk function for femur fracture

- Evaluate the risk function by means of reconstructing pedestrian impacts identified in the literature

- Learn how to pre-process, run, and analyze crash FE simulations using software commonly used in industy

The MSc-project is suitable for two students, preferably with good knowledge of the FE method, biomechanics, and scripting. The work will be carried out in a hybrid working model with occasional visits to Autoliv during spring 2026. FE simulations will be done using the LS-DYNA FE software. Students will be financially compensated for their work.

Main supervisor: Mohan Jayathirtha, mohankumar.jayathirtha@autoliv.com

Examiner: Johan Iraeus, johan.iraeus@chalmers.se

- Function

- Engineering, Development & Research

- Locations

- Autoliv Research - Vårgårda - ADS

- Remote status

- Hybrid

Autoliv Research - Vårgårda - ADS

Outstanding People Embracing Change

Our position as a worldwide leader in automotive safety systems, saving 37,000 lives every year, is achieved by our approximately 65,000 outstanding colleagues around the world. Their diverse assets, breadth and depth of expertise and desire to develop, in combination with Autoliv’s ambition to enable fulfilling careers, supports our vision of Saving More Lives.

About Autoliv Sweden

Autoliv is the worldwide leader in automotive safety systems. Through our group companies, we develop, manufacture and market protective systems, such as airbags, seatbelts, and steering wheels for all major automotive manufacturers in the world as well as mobility safety solutions.

At Autoliv, we challenge and redefine the standards of mobility safety to sustainably deliver leading solutions. In 2024, our products saved 37,000 lives and reduced 600,000 injuries.

Our ~65,000 colleagues in 25 countries are passionate about our vision of Saving More Lives and quality is at the heart of everything we do. We drive innovation, research, and development at our 13 technical centers, with their 20 test tracks.